The cone valve has a cone-shaped head that is fixed in a cylinder. It helps in spreading water and is specially used in dams or hydroelectric facilities. Also called the Howell-Bunger valve, these machines are found in expensive water systems and gas taps.

What are its components?

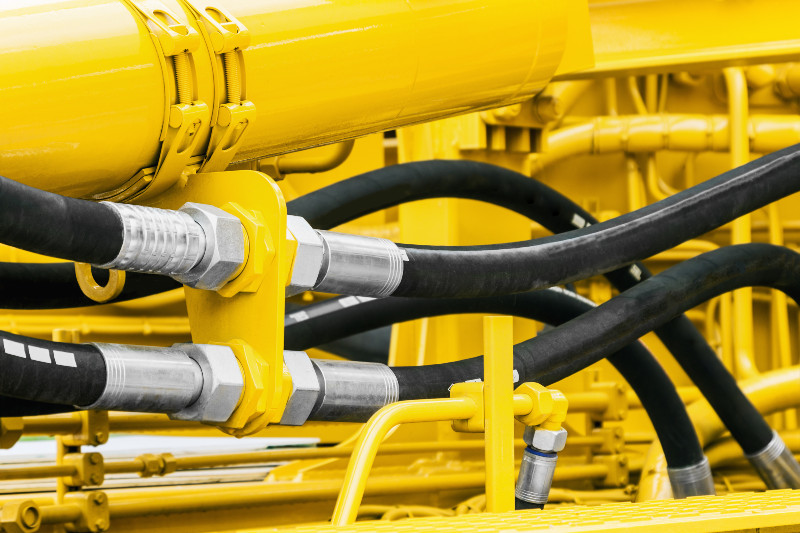

Cone valve manufacturers in India make the machine strong and highly dependable that can modulate the flow of water accurately under pressure, velocity and temperature. When you take a look at the cone valve, you will find three essential components:

- Actuation mechanism- It helps in fitting and rotating the plug.

- Plug- This is shaped like a cone and has a cylindrical bore.

- Body- It supports the plug and enables connection to the piping. It also supports the head that forms a strong base for the mechanism.

What are the applications?

- Cone valve offers unobstructed flow with minimised headloss and low pumping costs. Furthermore, there will be no backflow due to tight closure. As it comes with an uninterrupted cycle, water flow is accurately regulated.

- The cone valve is suitable for maintaining pressure or constant flow when combined with a regulating actuator and a flow pressure measuring device.

- It can shut off a pipeline as it gives drop tight closure and is widely used in situations where high pressures or velocities can occur.

The cone valve has a conical plug type that can be unseated with an axial motion. This is followed by a rotary motion to close or open the valve, which is again followed by the axial motion to reseat the plug. Cone valve manufacturers in India ensure that these machines are totally adaptable to the water flow at any installation site.