There are hundreds of millions of parts produced from aluminum on a daily basis. These parts may be small components used in appliances around the house, or they can be large parts used in aircraft, vehicles, or in heating and air conditioning systems in commercial buildings.

Regardless of where they are used and in what specific application they are created for, aluminum forging is one of the most common ways to create these parts. The process itself uses heat and pressure, either in the form of a steady pressure or impact pressure, to shape the aluminum quickly, efficiently, and precisely.

Precise Parts

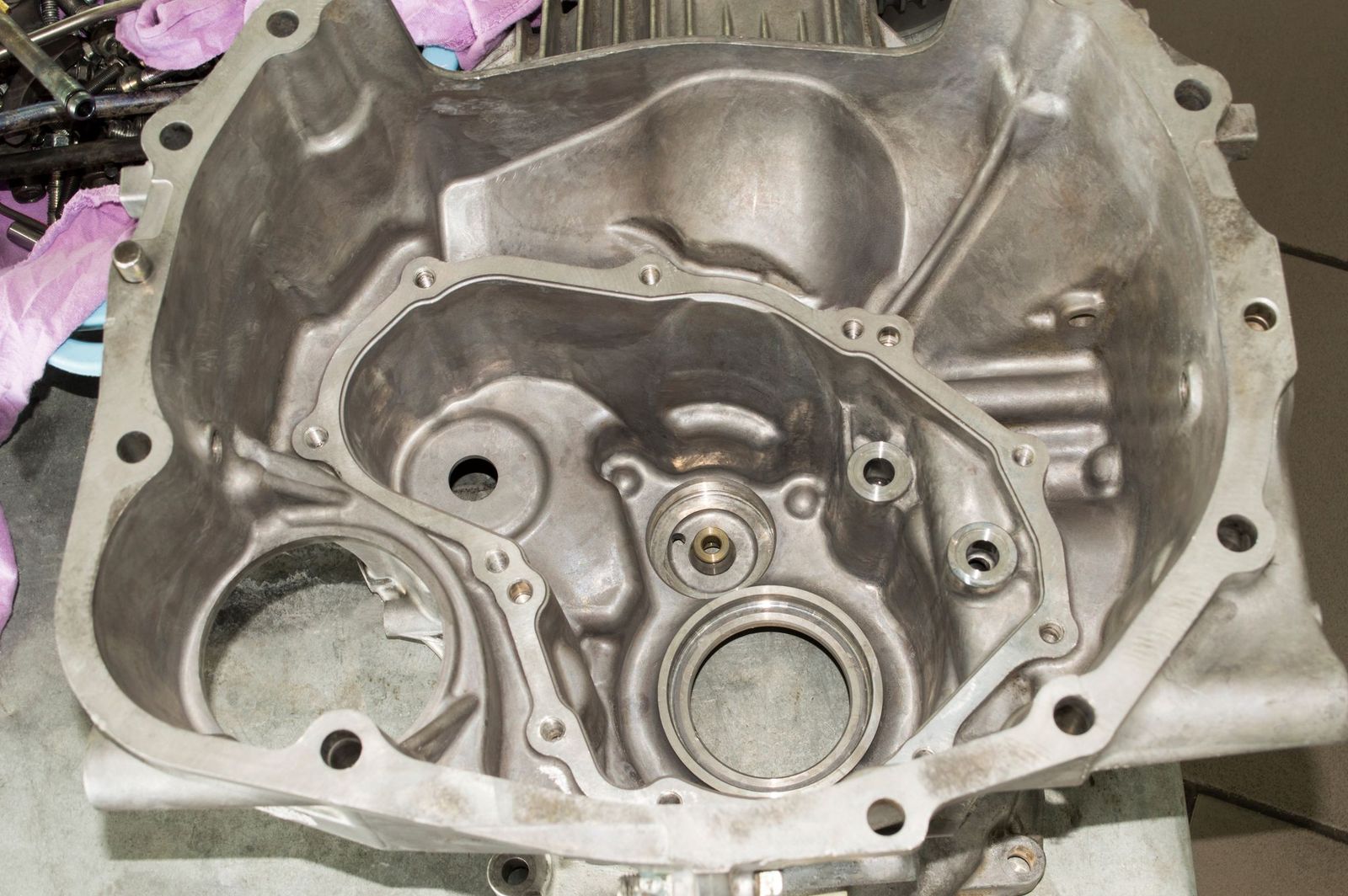

The best aluminum forging products are designed to meet specific tolerances. They can withstand the high pressure found in aerospace applications, as well as the high heat produced in automobile engines. At the same time, they are much lighter in weight than other types of comparable types of metals and alloys, which means they offer a superior strength to weight ratio.

The common mistake is to assume that aluminum forging products are only of a simple design and can only be used to create basic shapes. In fact, the process can be used to create elaborate and complex shapes, and it offers higher degrees of precision in these applications than multi-step or multi-operation methods to create the same part.

Cost-Effective Manufacturing

As a one-step process, aluminum forging products are made without joints, seams, or the need for several different machining and secondary operations. Altogether, this makes aluminum forging a much more cost-effective option.

With extremely limited waste material produced, and the ability to avoid secondary operations such as stress relieving, deburring, and welding, forging is increasingly a production method of top OEMs around the world.